ASX-listed high purity alumina hopeful, Altech Chemicals has finalised the terms of a staggered €5 million sale of a 25 per cent interest in German subsidiary, Altech Industries Germany to Frankfurt Stock Exchange-listed Altech Advanced Materials. Perth-based Altech, who retains ownership of the other 75 per cent of AIG, says it has now received the initial cash payment of €250,000 under the terms of the agreed deal.

ASX-listed high purity alumina hopeful, Altech Chemicals has finalised the terms of a staggered €5 million sale of a 25 per cent interest in German subsidiary, Altech Industries Germany, or “AIG” to Frankfurt Stock Exchange-listed Altech Advanced Materials, or “AAM”. Perth-based Altech, who retains ownership of the other 75 per cent of AIG, says it has now received the initial cash payment of €250,000 under the terms of the agreed deal.

Deferred annual payments of €1.58 million, beginning on the anniversary of the first up-front cash payment, will be made by AMM over the next three years, with an additional 3 per cent interest to be paid quarterly on the outstanding amounts. AAM also has the option to pay the outstanding deferred consideration in full at any time without penalty.

According to Altech, AAM will proportionally participate in all future capital raises by AIG on the same terms as Altech for the purpose of funding AIG’s working capital and envisaged business development activities. These include the exercise of its option to acquire industrial land at the Schwarze Pumpe Industrial Park in in the eastern German State of Saxony.

In October, Altech received a letter of commitment from Saxony’s Ministry for Economic Affairs, Labour and Transport for a grant of €7.38 million to support the company’s total CAPEX for the possible construction of a second high purity alumina plant at the Schwarze Pumpe Industrial Park in addition to Altech’s already proposed operation in Malaysia.

Altech says it has kicked off detailed due diligence and a feasibility study to assess the viability of the high purity alumina plant in Germany.

The Saxony State Government offer came after AIG signed an option agreement to purchase about 10 hectares of industrial land in the Schwarze Pumpe Industrial Park in the Spreetal municipality of Saxony.

Altech Chemicals Managing Director, Iggy Tan said: “Selling 25 per cent of our German subsidiary to AAM will both assist in the future funding of AIG and with the due diligence and feasibility study work that has been initiated for a second HPA plant in Germany.”

Altech opened up a second technology front this year with its high purity alumina particle coating technology. The company says it has now successfully demonstrated its technology to coat particles of graphite with a nano layer of high purity alumina.

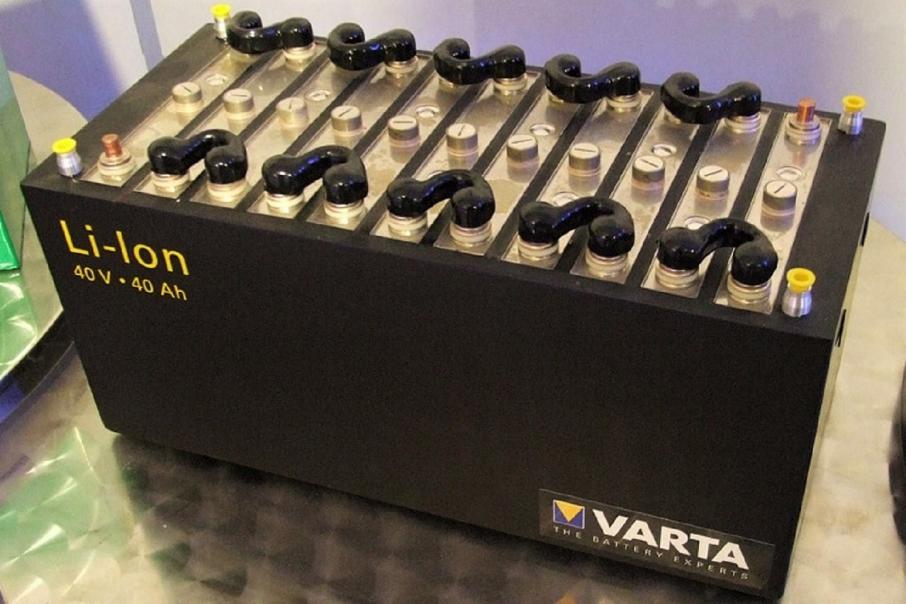

The graphite particles used are typical of those used in battery anode applications within lithium-ion batteries, according to the company.

Altech launched independent verification testing of its alumina coating of graphite particles three months ago.

A first-phase demonstration undertaken at Curtin University in WA in late November resulted in the application of a uniform and consistent two-to-three nanometre coating or layer of alumina on graphite particles.

The high purity alumina-coated graphite particles were then examined at the University of Western Australia under a transmission electron microscope, which showed a uniform and consistent alumina layer of about 2nm on the outer edge of the graphite particle.

Altech says the uniformity and consistency of an alumina coating on graphite particles is expected to be critical for improved lithium-ion battery life and performance.

High purity alumina is commonly applied as a coating on the separator sheets used within a lithium-ion battery as alumina coated separators improve battery performance, durability and safety.

According to Altech, there is an emerging use for alumina within the anode component of a lithium-ion battery due to the positive effect alumina-coated graphite particles have on battery life and performance.

Lithium-ion battery anodes are typically composed of graphite. In a lithium-ion battery, lithium-ion losses initially present as inactive layers that form during the very first battery charge cycle, with the losses compounding with each subsequent battery usage cycle.

Typically, about 8 per cent of lithium ions are lost during the very first battery charge cycle. This “first cycle capacity loss” or “first-cycle irreversibility” is a long recognised but as yet poorly resolved limitation that has plagued rechargeable lithium-ion batteries.

Currently graphite particles used in lithium-ion battery anodes are uncoated, however, Altech says manufacturers are now seeking to coat anode graphite particles with a very thin layer of alumina.

According to the company, tests have demonstrated that alumina-coated graphite particles have the potential to reduce first cycle capacity loss. It says the innovation can significantly increase battery energy retention, extend battery life and improve overall battery performance.

Altech now has its sights set on battery performance trials aimed at quantifying the potential lithium-ion battery performance and life-cycle improvements using its proprietary high purity alumina-coated graphite anodes.

Iggy Tan said: “We are very encouraged by the near perfect coating results from our technology which has the potential to significantly impact lithium-ion battery performance and address the problem of ‘first cycle capacity loss’. The next stage of work is battery performance testing using our alumina coated graphite, which will aim to demonstrate a step change in battery energy density capacity, performance and battery life.”

Altech’s links with Germany go deeper than AIG and AMM. It has German connections on its board and share register and relationships with leading engineering and construction outfit, SMS group and German Government-owned KfW IPEX-Bank.

The bank has provided a US$190 million debt funding facility as senior lender for Altech’s proposed US$280 million high purity alumina plant in Johor Bahru, Malaysia.

The company has previously indicated it is hoping to build the Johor Bahru processing plant in the next two to three years and ship first product to customers by about 2023. Management has proposed a design throughput capacity for the Malaysian plant of 4,500 tonnes of high purity alumina per annum.

In a world rapidly advancing towards a situation where lithium will essentially replace “oil” as the major input that powers automobiles, Altech is seeking out a place for itself in a massive ecosystem that looks set to rewrite the automotive sector story almost overnight.

Is your ASX-listed company doing something interesting? Contact: matt.birney@businessnews.com.au