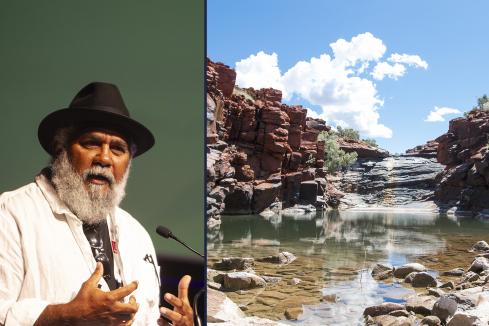

PLI has recently competed a modular build on a remote minesite that has changed the face of site administration buildings in the Pilbara.

In a game changing design, PLI consulted with their client to create a modular build to house vital communications networks at the Mesa J mine site in Pannawonica.

Boris Kovacevic, PLI Business Manager, said PLI engaged an engineering company to assist with the design and the region D compliance requirements.

“After discussing what the design requirements with the client were, we found that it was not a standard modular building in a box shape, they wanted something that was a little bit special and something that they wanted to create a different space for the workers on their site,” he said.

After consultation, the end design was an L shape module of four buildings and team went to work.

The scope included the design of the new building, removing the old infrastructure that was in place, and installing the new modular build and fit-out.

“There was a veranda lean-to and a lot of old concrete that had weathered away, so we ripped that out, we performed detailed earthworks on site, upgraded all the existing services that were there. We had our Hydro excavation truck on site but there was limited knowledge about where the existing services were.

We had the vac truck locating the services and assisting with upgrading the job and to give the client some knowledge of where the services were,” said Boris.

While PLI were decommissioning the existing buildings, locating services, and moving the client onsite into another workspace, they ensured operations were continuing with minimal disruption to the clients’ operations.

“We found another office space so the infrastructure and communications they needed were relocated to another building. We had a 24-hour period to get their comms back up and running before we commenced the upgrades and the removal of the existing infrastructure.”

The project was also PLI’s first Pilbara Manufacture turnkey project, on site at the company’s Karratha HQ over a three-month time frame.

“We’ve got our own fabrication workshop, a sandblasting and painting facility, so from the fabrication we manufactured our own jigs, put in the floor joists with our overhead crane, NDT tested the welds, blasted and painted, back into the workshop, put the floors in, stood the walls up had some assistance from a local vendor.

We try to use local as much as we can, we purchased all the sheeting the flashings and some of the flooring though local vendors and supporting local businesses in town,” said Boris.

“It (the building) was built in the workshop in the space of three months from start to finish. PLI did all the electrical, plumbing, kitchens and complete fit-out.

We manoeuvred the completed buildings out of the workshop and onto the back of trucks and over the course of two days, landed the buildings onto the concrete footings in Pannawonica.

Over the course of the next week, we completed the internal and external joinings and flashings, made the budlings cyclone safe and installed the verandas – that were fabricated in Karratha and trucked to site and installed in around 4 hours.

It saved a lot of risk and hot works having the frames completed in our Karratha workshop.” he said.

Once on site, PLI competed the full internal and external fit out including, cabinetry, plumbing and electrical.

Boris Kovacevic said PLI ‘s focus was to step outside the normal trend in modular site building and deliver something different.

“We wanted something that was new, innovative, we wanted to create a different space and that’s exactly what we delivered for the client,

To deliver the project from a purchase order to the installed works in the space of 6 months from purchase order to handing it over is something we are proud of.”